This week The Verge entered the intriguing and enigmatic world of Bugatti and got a close look at what goes into the making of their arresting Chiron supercars. Even though it was introduced just last year, the $2.6 million supercar is now a significant jewel in Bugatti’s crown and with the cars being in production now, the Verge has the grand opportunity to visit the Bugatti factory in Molsheim, in Alsace, France.

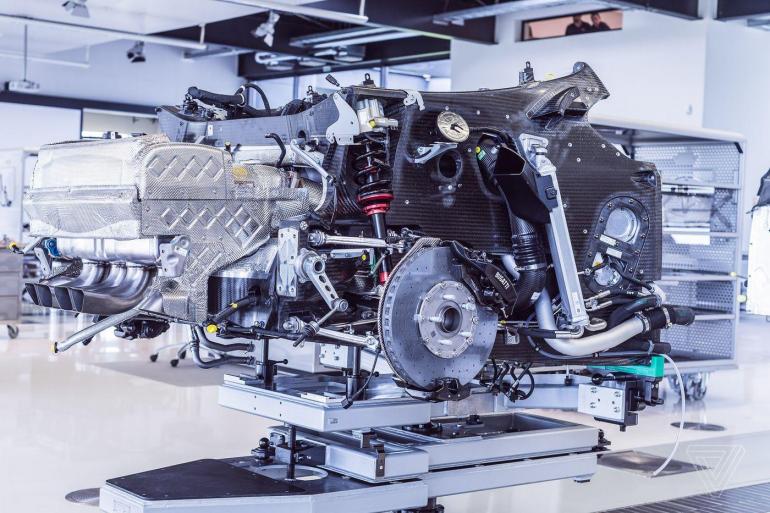

A total of six months goes into the production of each Chiron and no robots are used in the process. “The only electronic tool used in chassis assembly is the new EC nutrunner system. This allows a data curve of each bolt tightened on the chassis to be stored on a computer connected to the system, which then gives the assembly worker a signal when the right torque value is reached. There are more than 1,800 bolted joints on a Chiron, with documentation required for 1,068,” according to the company.

The 1800 pieces that comprise the car are put together by a 20 person team and customers are offered La Maison Pur Sang, a customization program that puts the clients in charge of their cars.

With a choice of 23 different colors of leather; eight different colors of Alcantara; 31 different colors of stitching; 18 colors of carpet; and 11 different seat belt colors at their disposal, customers have the chance to make their Chiron as unique as they like.

A 16-cylinder, 1,479-horsepower engine powers the car, pushing it to an impressive top speed of 261 mph.

Carbon ceramic brakes ensure that bringing the car to a halt even is a breeze, eve when you’ve been cruising at its top speed.

On the polished wheels are tires from Michelin that decrease the overall weight of the car.

The production team uses a light tunnel to discover any blemishes or imperfections in a thorough that’s a whopping six hours long.

During the two month long production, customers visit the atelier to check on the progress or even to participate in the assembly. The process may be long and pricey, but the end product is definitely worth it.

[Via:Theverge]