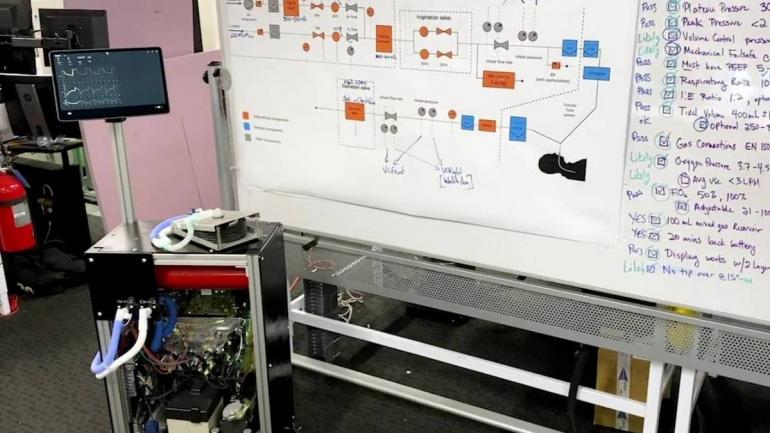

The coronavirus outbreak has turned into an unprecedented crisis that has stretched the healthcare system of many countries to the breaking point. Caught underprepared to tackle a pandemic of this scale, there is a huge shortage of medical supplies across the globe, including ventilators which are very crucial to keep critically-ill COVID-19 patients alive. Tesla is one of the automakers around the world that has stepped up to the challenge and is retooling its facilities to build ventilators. The electric car manufacturer shared a video update via Twitter and YouTube that gives a behind-the-scenes look of their engineering lab working on prototype ventilators built largely out parts for its vehicles. The reason why vehicle manufacturing giants like Tesla, Ford, and GM have been tasked with creating ventilators is that many crucial components for building the medical equipment can be sourced from the automaker’s parts bin. And, since car manufacturing has shut down during this period, these components can be put to use for this unexampled emergency.

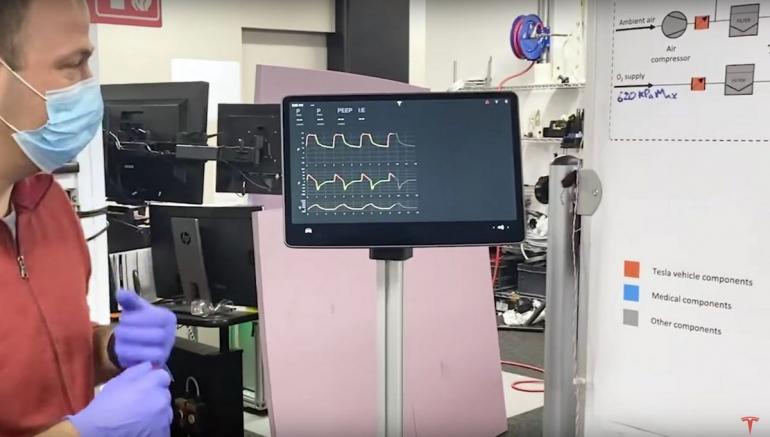

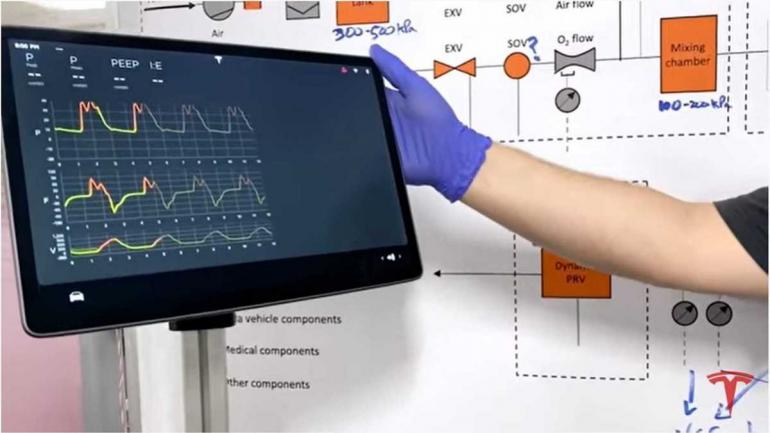

One of the Tesla engineers explain that the prototype ventilator heavily on Tesla car parts. It features a hospital-grade air supply system that feeds into a mixing chamber, where oxygen is mixed with air. The equipment is powered by a Tesla Model 3’s infotainment computer, which controls Model 3’s vehicle controller that takes care of the valves of the system. In addition to that, a suspension air tank is used as an oxygen mixing chamber and the Model 3 touchscreen is used as the interface. Elon Musk recently said that the Tesla New York factory will soon reopen to produce ventilators and this prototype might be the one that gets the approval for mass production and usage.

[Via: SlashGear]